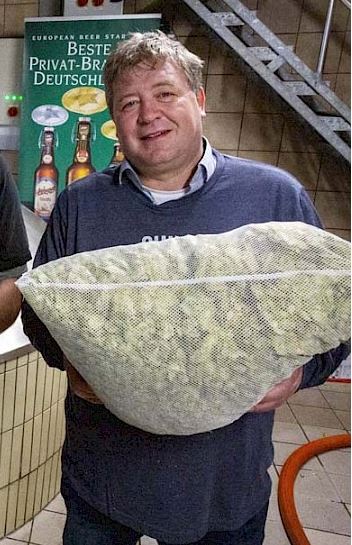

The brewhouse of the Kundmüller brewery dates back to 1975 and contains 50 hectoliters (1 Hl .= 100 liters) of beer per brew. Besides brewmaster Roland Kundmüller, the brewers carefully take care of the Weiher beer every day. And that is also necessary: Because brewing is a complex process.

The brewery decided to install a new palletizing system. The requirements were as follows:

- Instead of the old palletizing system, a space-saving, cost-effective and fully automatic palletizing system should be implemented in the warehouse.

- Existing connection points of the pack transport must be taken over, as well as existing conveyors must be reused → the customer demands a sustainable, resource-saving and economical approach.

- The output of the system at the filler is 10,000 bottles / hour or 500 crates / hour. This results in approx. 13 Euro pallets / hour.

- Universal retrofitting of different types of bottles and crates should be possible at any time and at short notice.

- Easy operation is particularly important:

- Double loading & double unloading of Euro pallets at predefined positions to ensure an optimal flow in the production and logistics of the brewery

- Intuitive control

- Traceable fault messages

- Pallet pressure control

- Control of running boards (presence and freedom from breakage)

- Control of blocks (presence and freedom from breakage)

- Easy service & maintenance possibilities

- Ergonomic accessibility at all system points

- Access possibility for a lift truck for the removal of bad pallets

- Maximum production interruption of four weeks to dismantle the old system and install the new palletizing system

The following solution was realized by Profipack:

- A solid and flexible robotic palletizing system with layer clamping head in a very confined space.

- 6 pallet mounting & dismounting positions

- Adaptation of the pack transport to the existing one

- Double loading & double unloading of Euro pallets on roller conveyor

- Pallet pressure control integrated in chain transport on unloading position

- Camera control with artificial intelligence for full boxes

- Delivery, installation and commissioning of the line including first production within three weeks

Unloader and loader for crates with a compact robot solution

The customer's feedback:

Many thanks to the company Profipack and the entire team for the extremely good cooperation regarding our project "New palletizing robot". We were and are very satisfied in every respect, from planning to installation and programming to commissioning. We would like to particularly emphasize the very fast and professional execution of the project. The Profipack team was at all times very competent, solution-oriented, flexible and responded to all change requests. We say: Anytime again!

- Roland Kundmüller -