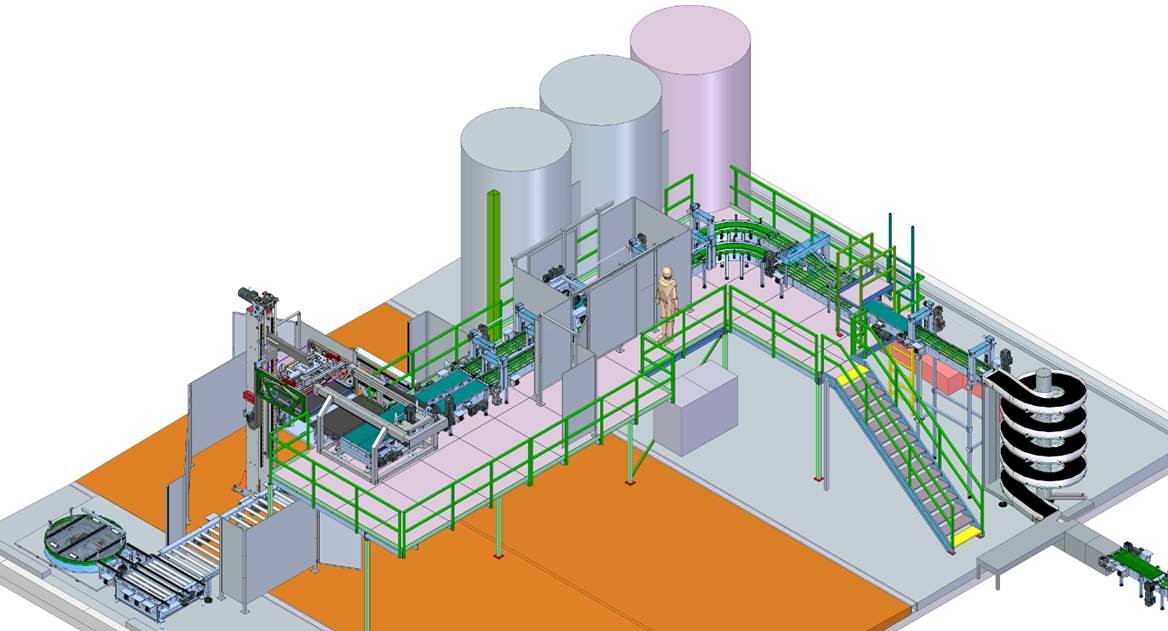

In Vorarlberger Ländle, the Rauch Fruchtsäfte company is renewing the palletizing of the PET line at its Nüziders site. The project scope includes a column palletizer with a built in shutter head in lightweight construction with carbon parts. The palletizer also handles intermediate layers and is installed on the lifting column to save space. The grouping station with row pusher and two pack feed belts groups the packs into one layer. The special feature of the grouping station is the two-lane, patented, external servo pack turning station and the servo controlled grouping without gap divider onto two mat belts. This enables trouble free processing of small PET packs. The connection to the line is made with stainless steel pack conveyors and is guided upwards by a space saving spiral conveyor. The entire pallet transport system is also made of stainless steel and is designed for Euro- and industrial pallets. At the end of the Profipack scope of supply, the pallet conveyor connects to the existing system, which leads into the high bay warehouse.

The new line enables Rauch to process its very high quality products at a line capacity of 47,000 bph. The energy savings as well as a very good accessibility of the compact plant for operators and technology were decisive for Rauch to bring this production area back to the state of the art. The professional installation and the great commitment of the Profipack employees also convinced Rauch.