Wine in Bags

And once again, Profipack was able to prove that innovation and sustainability are of paramount importance.

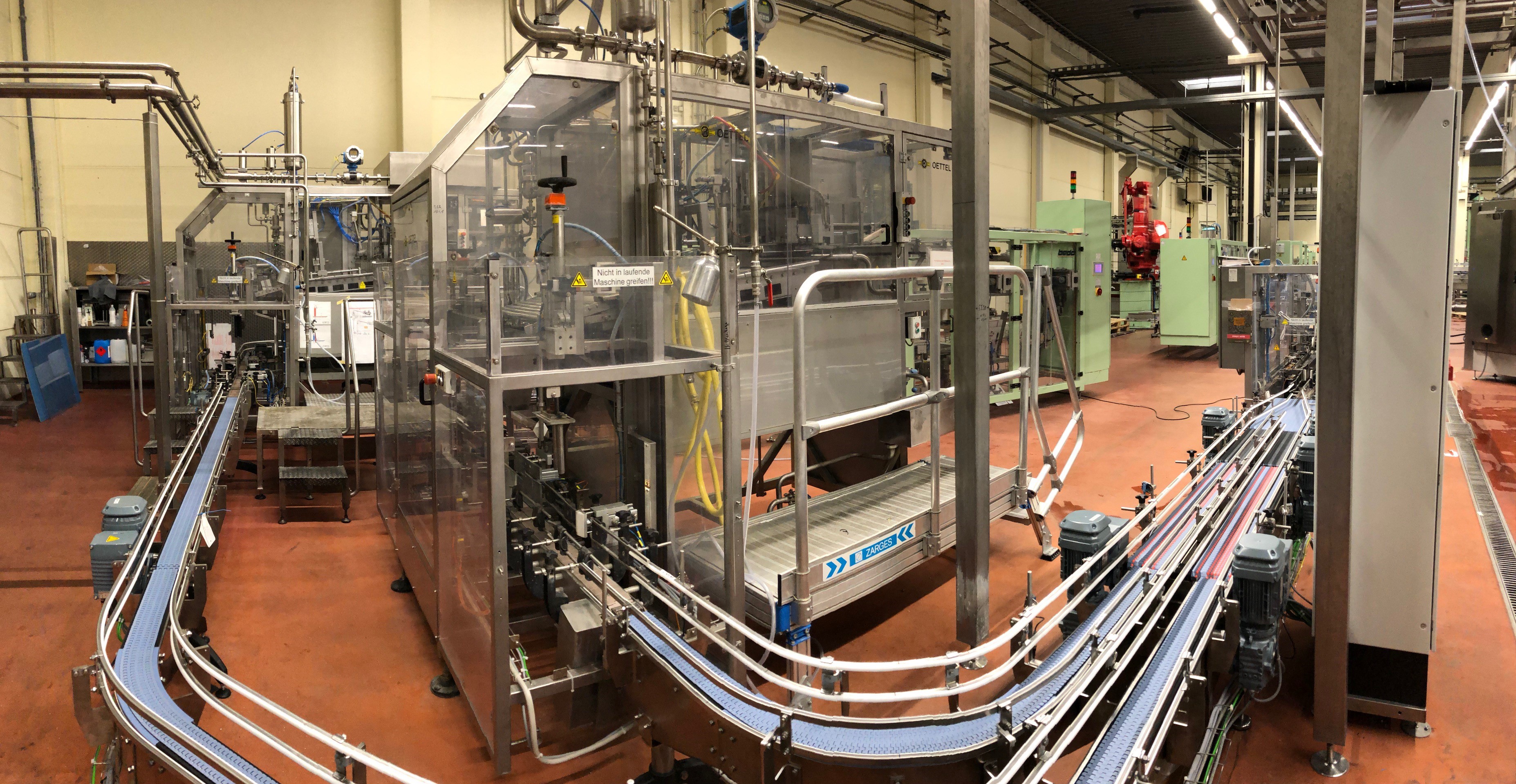

When Reh Kendermann GmbH enquired about a new filling line, Profipack immediately knew what to do. Thanks to fast and accurate planning, the first layout proposal was immediately drawn up, complete with a detailed cost estimate. After a few optimisations, the customer did not think twice and decided to tackle the project with Profipack.

The special thing about this project was the product itself. It was wine that was filled into bags. These bags were then placed in boxes by a packer, fitted with a handle and stacked on pallets. These containers are also known as pouches. This term will be used even more frequently in the future, as the product has an ecological footprint that is up to 80% lower than that of a conventional wine bottle.

A particularly efficient arrangement of the production line also saved time and money. The following machines were used for the order:

PROFIROB

PROFIPACKER

PROFITRANS

Carton erector

Carton sealer

Supplied system details

Robot Palletizing

The robot, which is equipped with a louvre head, takes on the task of placing the packs arriving on a conveyor belt precisely onto a pallet. The following pallets can be processed in the system with a total of seven sizing patterns: Euro pallet, industrial pallet and quarter pallet.

Thanks to the efficient performance of the robot, the pallets can be placed effortlessly in their intended location. If required, the palletiser picks up a pallet and places it on the pallet track to initiate the palletising process.

Transporters

The conveyors in the line are divided into pack transport and pallet transport. The special feature of container transport is that the closed pouches are rotated through 180° by a drop mechanism without damaging the product. In contrast, pallet transport is used in the simplest possible design to save as much space as possible. This consists of two roller conveyor segments.

Packer

Although the bags fall directly into a box after filling, they are placed in a transportable box again. This work is carried out by the Profipacker 1200. It precisely places the small packs into the carefully erected carton. There are five different attachments for the machine, which make it possible to process all carton formats with the same machine.

Depending on the output, the packer can place two packs next to each other and precisely aligned in the end product.

Cardboard processing

Purchased machines from Bedo are used for folding and closing the cartons. Three carton erectors, model series 12, type VA 1215, and two carton sealers, model series 32, type VA 3225, are used. The articles are labelled and coded before the machines so that a planned flow of goods is possible.

About the client

Reh Kendermann

The headquarters of Reh Kendermann GmbH Weinkellerei is located in Bingen. Other company sites are located in Leiwen and Gau-Bickelheim. Reh Kendermann also has its own winery with 252 hectares of vineyards in Oprisor, in south-west Romania. They import wine brands bottled in the country of origin to Germany. As Germany's largest export winery, they also bring German wine to the whole world. One of their special flagships is the world's most successful branded wine from Germany: Black Tower. With over 15 million bottles sold each year, Black Tower is the world's favourite German wine brand.